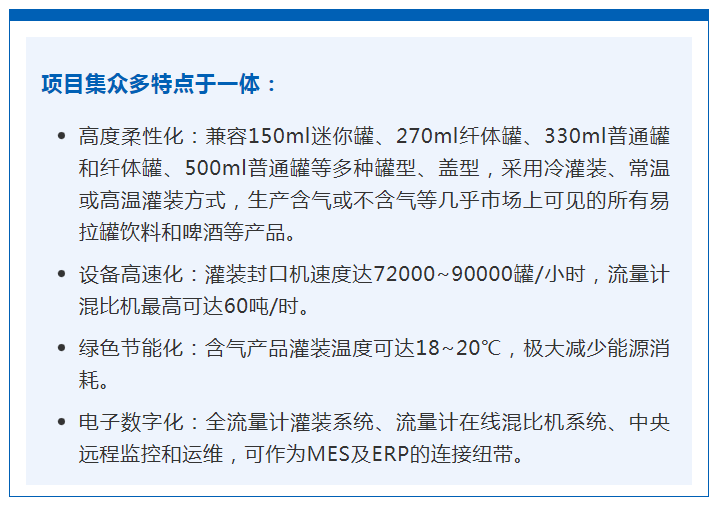

Zhongchen Light Machinery has cooperated with Jianlibao and A.S. Watson to produce a super-high-speed flexible production line for easy-open cans with a capacity of 72,000 to 90,000 cans per hour, which can perform both hot and cold filling.

Zhongchen Light Industrial Machinery has successively cooperated with Jianlibao and Watson's to produce 72,000 to 90,000 cans per hour high-speed aluminum can cold and hot dual filling multi-can type flexible production lines, marking the grand debut of domestic ultra-high-speed production lines and representing another major scientific and technological progress in the liquid food light industrial machinery equipment industry.

The Zhongchen Light Industry's 72,000~90,000 cans/hour aluminum can high-speed production line was launched as a key design project early on, with over 100 running cases of medium-high speed and super-high speed aluminum can production lines from 36,000 cans/hour to 90,000 cans/hour in the market, serving hundreds of domestic and foreign users including PepsiCo, Wahaha, Heineken, and Snow Brewery, and accumulating valuable experience in design, manufacturing, and operation.

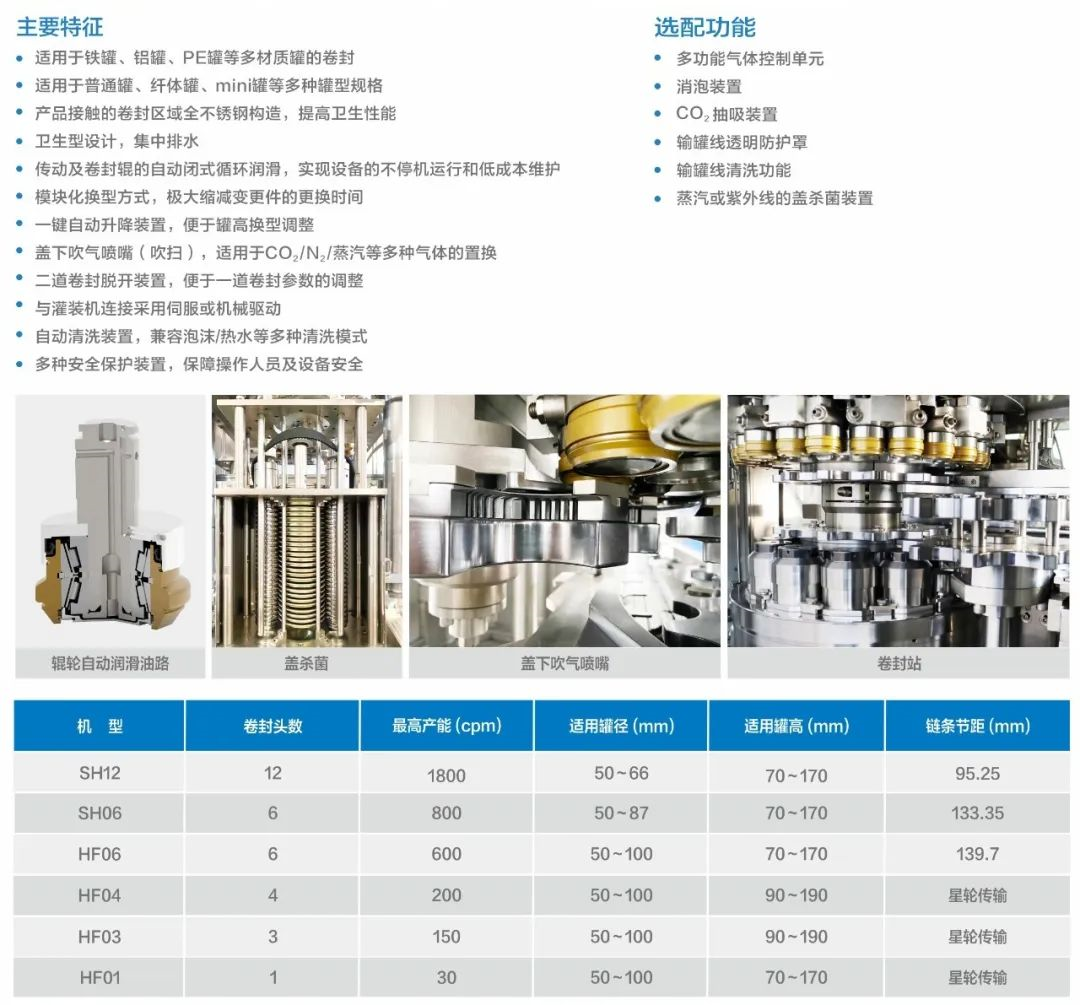

Zhongchen Light Industrial Machinery Co., Ltd. also has a full range of 6-head and 12-head mid-to-high-speed sealing machines with independent design and manufacturing. Among them, the 12-head sealing machine has a maximum speed of 110,000 cans per hour, truly realizing the domestic design and manufacturing of high-speed sealing machines for aluminum cans.

Recommended News

-

Hefei Zhongchen Blow-Fill-Cap Beverage Production Lines Empower Clients to Open New Chapters in African Beverage Business

2025-08-20

-

The Budweiser APAC Equipment Manufacturers Strategic Alliance Technology Forum Grandly Opens at Zhongchen Machinery.

2025-06-25

-

ABInBev Group visited Zhongchen Light Machinery

2025-03-15

-

Good News |Hefei ZhongChen(HF.ZCQJ)Honored with Carlsberg Group's "Outstanding Supplier" Title

2025-05-13

-

CBST 2025 Successfully Concludes: Zhongchen Light Machinery Shines on the "Digital, Intelligent, and Green" Stage

2025-03-07

-

CBST 2025 Successfully Concludes: Zhongchen Light Machinery Shines on the "Digital, Intelligent, and Green" Stage

2025-03-07

-

Fun Welcoming the New Year | Exciting and Thrilling! Zhongchen Light Machinery’s Sports Event Was a Blast!

2025-01-20

-

The governor of Anhui Province, Wang Qingxian, visited Zhongchen Light Machinery to investigate its digital transformation progress.

2024-12-10

-

CBB 2024 | Zhongchen Light Machinery Makes a Grand Appearance!

2024-11-27

-

CBB 2024 | Zhongchen Light Machinery Makes a Grand Appearance!

2024-11-27